To receive the latest news updates from Convergent, please subscribe to our mailing list.

SUBSCRIBE

Recent news from Convergent:

Purdue Composites Design & Manufacturing HUB (cdmHUB) invites you to a series of webinars presented by global composites experts. These webinars examine the history, present capabilities, and future of composites science and technology, with the goal of sharing the vast knowledge of composites that has been developed over the past 50 years.

https://www.purdue.edu/cmsc/events/2020-webinars/

Dr. Anoush Poursartip, The University of British Columbia

- Director, Composites Research Network

- Co-Director, Composites Knowledge Network A Canada Networks of Centres of Excellence – NCE

- Director of Research Convergent Manufacturing Technologies

Dr. Poursartip opens Purdue Unviersity's Global Composite Experts Webinar Series with a presentation on, Digital Disruption of Composites Manufacturing & Design.

Presented: September 10, 2020 at 11am-12pm Eastern

Speakers & Registration https://www.purdue.edu/cmsc/events/2020-webinars/#speakers

Dr. Sanjay Sharma, Global Leader of Advanced Modeling - R&T at Hexcel, presents this webinar on "Using Simulation for Composite Materials Parts Design." Convergent is proud to be a part of Hexcel's integrated computational materials engineering (ICME) workflow. As part of this presentation, Dr. Sharma demonstrates the utility of Convergent COMPRO to simulate and solve composites processing challenges. In addition to COMPRO, Convergent provides a full suite of software, hardware, and services to support data and simulation development and production of advanced composites. If you'd like to learn more about integrating ICME into your workflows, please contact Convergent.

https://hexcel.eventbuilder.com/event/24604?source=Hexcel

Presented By

Sanjay Sharma

Global Leader Advanced Modeling - R&T

Hexcel

Dr. Sharma brings more than 15 years of learning about composite materials using a simulation driven approach. He leads a team at Hexcel R&T credited with innovative techniques applied at the intersection of Materials Science and Structural applications. He counts himself to be fortunate to have been assisted by capable colleagues and team members.

He has a PhD in Mechanical engineering from Wichita State University.

As part of the CCMRD team including Boeing Canada – Winnipeg, Magellan Aerospace, ASCO, PCM, AVCORP, National Research Council, Red River College, Composites Research Network – University of British Columbia and the Composites Innovation Centre, Convergent has been awarded the Manitoba Aerospace Award of Excellence for Innovation and Technology Development. For more information, see http://mbaerospace.ca/all-stars-awards-winners/

Convergent invites you to visit our booth at CAMX, Oct 16-18, in Dallas TX.

Convergent has joined Canada's Digital Technology Supercluster to accelerate development of Digital Twins for composites manufacturing.

Convergent is exhibiting at SAMPE Long Beach, May 21-24. Please stop by our booth and let us show you some new and exciting products.

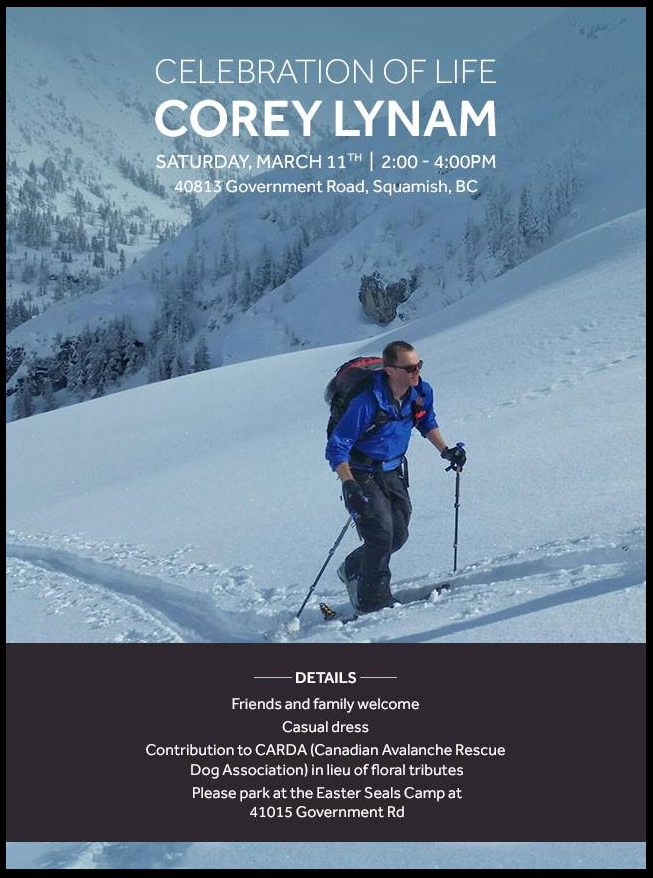

Our dear colleague, Corey Lynam, Engineering Lead, Analysis Application, has passed away in a tragic accident.

We regret to inform our dear customers, colleagues, collaborators and friends that Corey Lynam, Engineering Lead, Analysis Applications died in an avalanche whilst skiing the backcountry of Callaghan Valley near Whistler, BC on Saturday March 4th, 2017.

Link to CBC news article - Corey Lynam, Avalanche Callaghan Valley

Corey was highly valued and a rising star at Convergent, destined for great things, loved by his colleagues, and appreciated by his customers and collaborators. We are devastated and thank all of you who have reached out to us.

We have reached out to all who worked in any capacity with Corey. If by any chance, we have missed any detail please contact us immediately.

Convergent Manufacturing Technologies is exhibiting at JEC World in Paris on March 14, 15 and 16, 2017.

We welcome you to our booth, #C49 in Hall 6 at the Paris Nord Villepinte Exhibition Center. Come see our live demo of the COHO system.

Convergent Manufacturing Technologies was awarded the 2016 Silver Boeing Performance of Excellence Award.

The Boeing Performance Excellence Award and Supplier of the Year are Boeing's official programs to recognize suppliers who achieve the high performance standards necessary to meet customer expectations and remain competitive in the global economy. The Boeing Performance Excellence Award (BPEA) is an annual program to recognize superior performance as measured in BEST. In order to receive an award, a supplier must maintain a composite performance rating of either silver or gold for each month.

CAMX 2015 is just around the corner and Convergent is excited, not only to be exhibiting real time leak detection and localization (COHO) and process simulation (COMRO and RAVEN) with live demonstrations, but also to be finalists for the ACE Award. The "Awards for Composites Excellence (ACE), a prestigious composites industry competition, recognizes outstanding achievement and innovation in technology, manufacturing and product development”.

COHO is a manufacturing aid that revolutionizes detection and localization of vacuum leaks in composite processing, resulting in large productivity increases. It is currently used by the large aerospace OEM's to increase productivity when bagging large and complex composites parts. COHO is designed for composite manufacturers where high vacuum integrity is required, such as in aerospace and wind energy applications.

We would love for you to stop by our booth, G64, so that we can talk about how your organization could realize the significant benefits of our COHO system.