EVALUATE

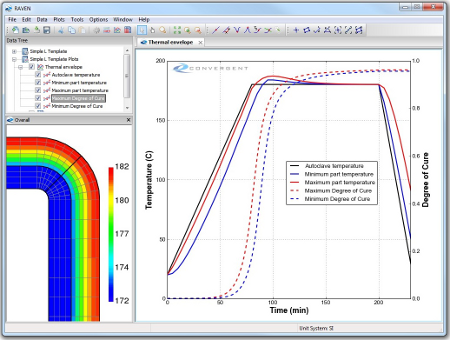

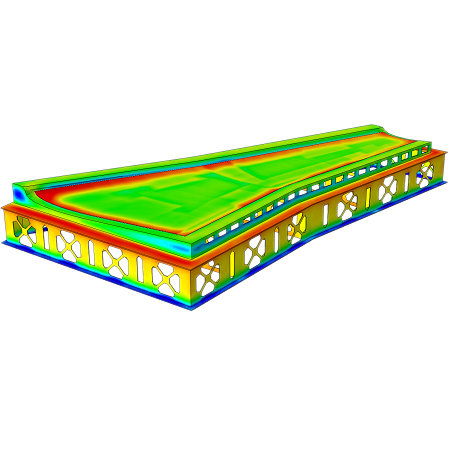

Determine the effect of process parameters on the finished product before it is manufactured.

DESIGN

Develop more robust and efficient manufacturing processes to lower manufacturing cost.

TROUBLE-SHOOT

Find root causes to manufacturing problems and quickly evaluate different solution strategies.

DETECT

Rapidly identify and locate vacuum leaks in bags and tools through integrated sensor technologies.

CUSTOMERS

Our customers include over two thirds of the top twenty aerospace companies world-wide.

Convergent's products and services are designed for anyone involved in advanced composites manufacturing.

We support the whole supply chain from materials suppliers, tool and equipment manufacturers, to part manufacturers and OEM's.

NEWS

In addition to the major release of RAVEN last month, Convergent is pleased to announce the newest major release of COMPRO, V2024.0.0.

Convergent is pleased to announce the newest major release of RAVEN, V3.16.0. This release incorporates new or recently added open mater